Panevo’s ioTORQ platform continues to evolve, introducing Machine Learning AI for process water conservation.

Panevo, a leader in industrial energy management and resource conservation, in collaboration with PepsiCo, showcased their innovative approach to addressing water scarcity challenges at The Water Expo 2024 in Miami, Florida from August 20th to 22nd. This initiative advances the use of Industry 4.0 technologies to optimize water performance for the food processing sector.

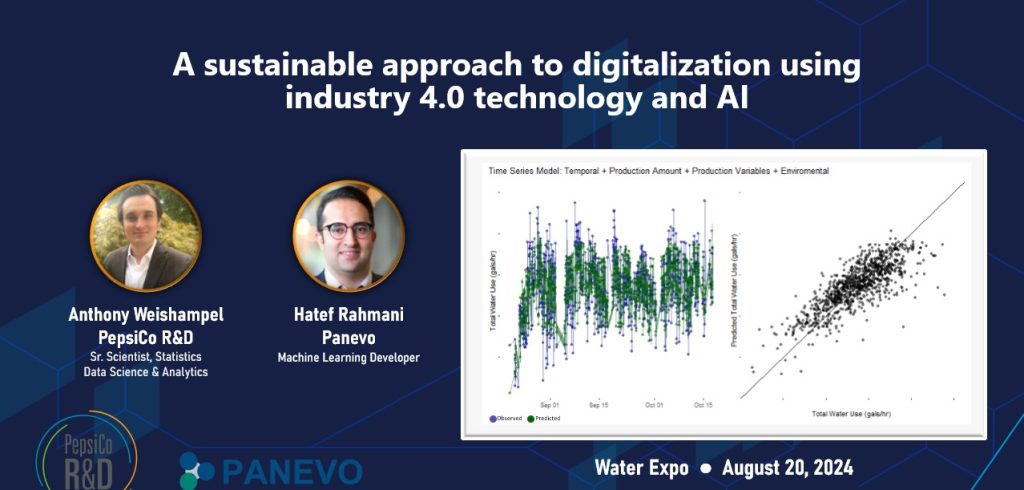

The project, funded by PepsiCo, involved the strategic installation of digital flow meters and sensors on snack food production lines to capture detailed water use data. With this high-resolution real-time data, Panevo developed high-accuracy machine learning models to predict water consumption. These algorithms detect anomalies in water usage by evaluating a wide range of production metrics, equipment interactions, and environmental data to help sites proactively manage their water use.

A key innovation of this project involves continuous learning algorithms that incorporate feedback from site personnel to categorize and respond to detected anomalies. This fosters a causation feedback loop, where real-time data insights improve water use efficiency on an ongoing basis. The implementation is currently being rolled out across multiple PepsiCo sites in North America and has identified water savings potential of over 10% on some process lines, without the need for capital investment. By integrating these advanced AI-driven solutions, PepsiCo is reinforcing its commitment to responsible water management and sustainable manufacturing practices.

“We are thrilled to be working with PepsiCo on such a vital project,” said Craig Holden, Panevo CEO. “Water conservation is a critical challenge for the industry, and by applying advanced AI and machine learning techniques, Panevo is creating practical solutions that can make a material difference to sustainability performance.”